In addition to gutter and downspout design, the functionality and long-term performance of your roof drainage system is critical. If not designed with sufficient capacity, quality of materials and finish, and correct installation, the building structure is vulnerable to roof leaks, structural degradation to both roof and wall structures, foundation leaks and/or decay, and ground erosion.

For projects where a half round gutter system or custom box gutter system is being considered or required, we encourage you to use some or all of the attached specifications: Half Round Gutter Specification, Custom Box Gutter Specification. It will ensure the roof drainage system is visually appealing and functioning as designed for many years to come.

Following are important details for your gutter and downspout design consideration. As always, please feel free to call (706-692-7333 extension 1) or email (sales@rdcaa.com) Roof Drainage Components if we can assist you in your gutter and downspout design and/or specifications regarding your roof drainage system.

Variables that should be considered in determining a properly functioning gutter system include:

- Drip Edge to Gutter Overhang

- Gutter Support Capacity

- Rain Fall Intensity

- Slope of Gutter

- Slope of Roof

- Spacing and Size of Outlet Openings

- Style of Gutter

- Is there potential for water freezing in the gutter?

Please go to the spec builder page to correctly design and size your gutter.

Specifying the correct size, quantity and location of downspouts is critical for effectively draining precipitation away from your building over the long term.

Following are the key variables:

- Rainfall Intensity?

- Slope of Roof?

- Is the gutter connecting to the downspout pitched?

- Downspouts of less than 7 square inches should be avoided.

- Is the size of the downspout constant throughout its length?

- Downspouts longer than 40′ should utilize conductor heads to avoid creating a vacuum.

- Do the downspouts have offsets? If so, how big? Large offsets adversely affect drainage.

- Outlet tubes should match the downspout size.

- Does the downspout size fit the inside width of the bottom of the gutter?

- Can you securely fasten the downspout to building throughout its entire length?

- Is there potential for water freezing in the gutter or downspouts?

- Is the downspout in a location acceptable for water discharge?

Please go to the spec builder page to correctly design and size your downspout.

In deciding how to best install the gutter, consideration should be given to:

- Appearance

- Expected Life

- Ice Loading

- Size of Gutters

- Material

- Expansion

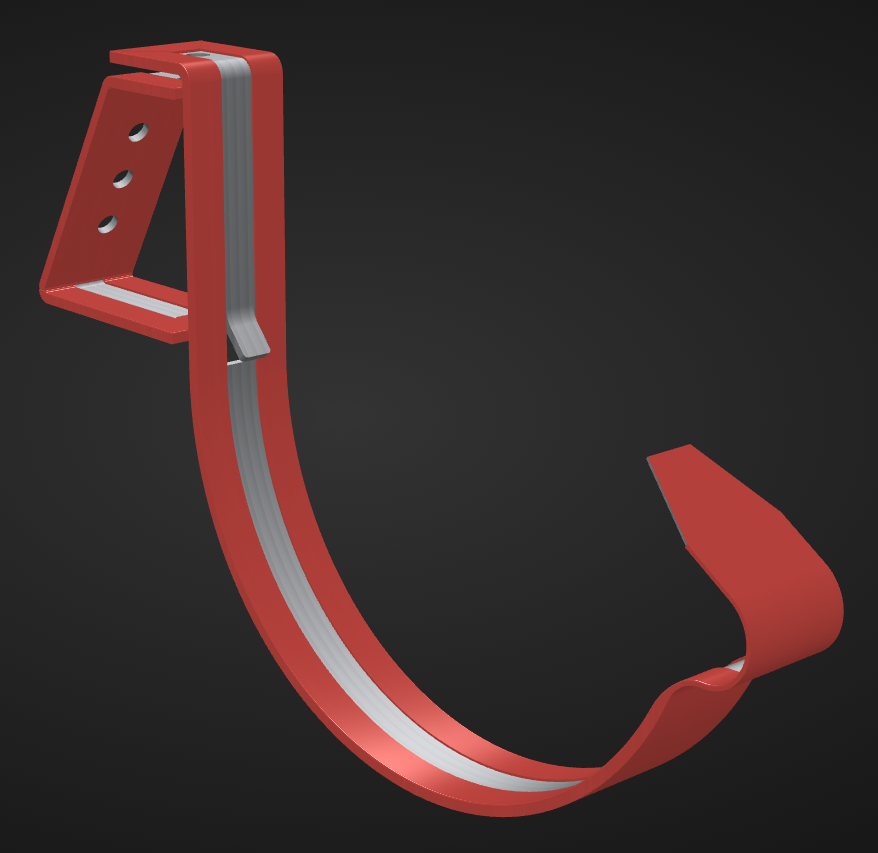

General Discussion – Half Round Gutter:

Regarding all half round gutter profiles external gutter support is always warranted. As there is no vertical back to half round gutter that can be supported by a vertical fascia, any downward pressure on the gutter puts excessive stress (leverage) on internal hangers leading at the very least to gutter ‘sagging’ over a period of time. Under ice load conditions, internal hangers will experience metal fatigue and given enough ice loading, over time failure can occur. There are various external gutter support brackets available for half round gutters that offer sufficient support to withstand repeated ice loading and high wind condidtions. However, in addition to the criteria listed above, half round gutter installation often involves additional considerations unique unto itself.

Specifically:

- Is the half round gutter the same diameter for the entire project?

- If not, for a uniform appearance throughout the project, it is important to verify the style of gutter support bracket you are selecting is available for all gutter sizes.

- Can the half round gutter support brackets be mounted in the same manner for the entire project?

- Once again, if the gutter is being mounted on different roof pitches, fascia angles, (or perhaps no fascia at all), rafters and/or there are different sizes of gutter involved, it is important to confirm the gutter support bracket selected can meet all of the different mounting geometries you require. In addition, for said geometries you should ensure the gutter support brackets maintain a uniform appearance throughout the entire project.

- Is there box or k-style gutter on the project in addition to half round gutter? If so, does the appearance of gutter support brackets used for the half round need to match the box and/or k-style brackets?

- Usually box or K-style gutter do not require the frequency of gutter support brackets as half round gutter. Box gutter and K gutter support brackets are spaced typically 48″ on center, while half round brackets are typically 24″ on center. To preserve a uniform appearance between your half round gutter and ‘K’ or box style gutter brackets, make sure you specify a strong enough half round bracket to accommodate the wider spacing used for box and K style gutter. In addition to providing for a better looking installation it also saves money in material and labor.

- Is the color/paint warranty for the support brackets the same as the gutter itself ensuring a long-term, attractive appearance?

- Most pre-painted commercial gutter, be it steel or aluminum, carries at least a 20 year paint warranty. Most half- round gutter supports brackets are post-painted to match, but carry no paint warranty. Almost without exception the bracket has a paint system that at the very least will fade or chalk long before the gutter. To avoid this mismatch in performance it is best to require a gutter support bracket that is either galvanized or stainless bar stock and then wrapped on all exposed surfaces with the same pre-painted steel or aluminum material used to fabricate the gutter. (See Figure)

General Discussion – Box and K-Style Gutter:

Internal hangers:

Even when ice or heavy snow is a possibility, if the girth of the gutter is 20″ or less and the back side of the gutter is vertical and supported from top to bottom by a vertical fascia, it is common to use only internal gutter hangers. Internal hangers are relatively inexpensive and easier to install than external gutter support brackets. If you elect to use internal hangers only (without any external support brackets), they should be spaced at a maximum of 24″ on center. Closer spacing is prudent where snow or ice loads are common. The possible issues that can arise from using only internal hangers are two-fold:

- After repeated ice or snow loads some gutter ‘sag’ is likely even though total gutter failure may not be a concern.

- Internal gutter hangers must be secured with screw(s) going through the back of the gutter into the fascia board. Whenever a screw hole is put into the back of gutter, due to the gutter expanding and contracting, the screw hole can become enlarged and, as a result, moisture can become trapped between the gutter and fascia causing corrosion and/or rotting. Further, the expansion and contraction of the gutter over time can cause the screw(s) that secure the internal hangers to the fascia to become loose, jeopardizing their effectiveness.

Should you elect to go with just internal hangers you should keep spacing to a maximum of 24″ on center and use the same base metal as the gutter or stainless steel. In addition, up through an 8″ length, it is suggested your internal hangers be at least .062″ thick stamped aluminum or steel or .050″ thick stamped stainless steel. If your internal hanger is to be longer than 8″, it’s suggested either .125″ x 1.0″ or .1875″ x 1.0″ galvanized or stainless bar stock be used at a maximum of 24″ on center.

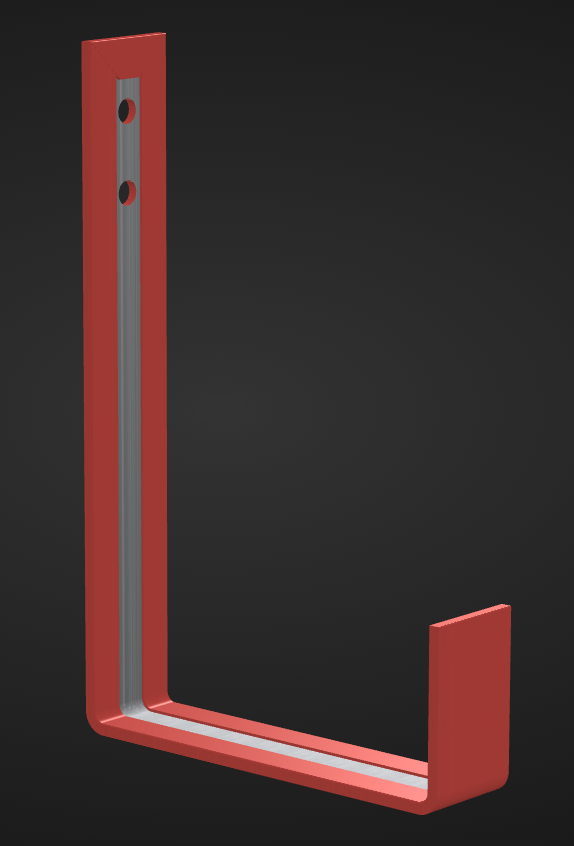

External Support Brackets

When using external gutter support brackets some internal gutter hangers are still necessary. The internal hanger ensures the gutter maintains its structural integrity during loading. Best practice is to alternate between internal hangers and external support brackets with a maximum of 24″ on center ( for gutters with 20″ girth or less) between internal hanger and external gutter support bracket. For gutter with a girth exceeding 20″ spacing between internal hanger and external support bracket of 18″ on center is certainly appropriate depending upon the building location, roof pitch, roof size and mounting detail.

Other Support Bracket Considerations

Important product features to consider when designing or selecting external gutter support brackets are:

- Strength

- Ease of Installation

- Appearance

- Expected Life

For both box and K-style gutter, if the back of the gutter is vertical and being mounted directly against a vertical fascia that extends from the top to the bottom of the gutter, .125″ x 1.0″ steel or stainless bar stock is sufficient in strength. Aluminum bar stock is not suggested as it does not have the strength of steel or stainless. If you elect to use steel bar stock make sure it has either a galvanized or zinc coating equivalent to at least G-90 or AZ-55 respectively. This nearly eliminates the risk of any corrosion over the product’s lifetime. If the gutter does not have a completely vertical back side supported by a vertical fascia, a .1875″ x 1.0″ support bracket is suggested which provides additional strength.

To help make installation go smoothly, make sure you specify the placement of the screw holes on the back of the gutter support bracket. This will help ensure correct horizontal orientation during installation. In addition, make sure all of the bend angles on the gutter support bracket are the same as the gutter itself.

Most commercial gutter support brackets are post-painted after fabrication to match the color of the gutter. While this may be acceptable when the product is installed, the brackets will fade and discolor quite differently as compared to the gutter. To make sure the support brackets maintain the same appearance as the gutter for the entire life of the gutter, it is best to specify the bar stock be wrapped in the same color pre-painted aluminum or steel as used for the gutter. In addition, require that the metal that is used to wrap the bar stock cover all 4 sides of the bar stock with the exception of a small area where the metal wrap meets on the unexposed side of the bracket. (See Figure)

There are four primary metal categories to select from when choosing your roof drainage components:

- Aluminum

- Steel

- Copper

- Stainless

When you are deciding what material to go with, there are four basic considerations:

- Appearance

- Cost

- Functionality

- Longevity

If fabrication and installation are done correctly, all four metals have excellent functionality. When constructed correctly and installed as designed they are not susceltable to leaking and will last for many years, barring abuse. When reviewing your options from a cost perspective, generally speaking steel is the least expensive, followed by aluminum, stainless and copper in that order.